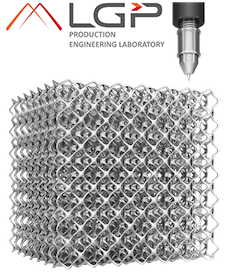

The ENIT Production Engineering Laboratory (LGP, EA 1905), which is multi-disciplinary, have a Mutualized Structure Research («SMR», Financed by Occitanie Region and Europe) with companies covering the entire value chain of metal additive manufacturing on powder bed (3D machines builders, powder making, designers, 3D printers companies, end-users). This technology transfer structure is open to companies of all sizes to support their innovation processes in the field of additive / 3D metal manufacturing.

The ENIT Production Engineering Laboratory (LGP, EA 1905), which is multi-disciplinary, have a Mutualized Structure Research («SMR», Financed by Occitanie Region and Europe) with companies covering the entire value chain of metal additive manufacturing on powder bed (3D machines builders, powder making, designers, 3D printers companies, end-users). This technology transfer structure is open to companies of all sizes to support their innovation processes in the field of additive / 3D metal manufacturing.

PARTNERS :

WORKFORCE :

- 2 dedicated engineers: Dr. Pierre SELVA (calculations and measurements): Mr. Antoine VEZIRIAN (production).

- 1 scientific manager: Dr. lionel.ARNAUD@enit.fr, +33 6 22 96 64 90

- 1 Administrative Manager and projects manager: Mr. Vincent RÉMY.

- Support of the 6 researchers of the D2PAM Team and also of the 54 teacher-researchers of the LGP laboratory, covering mechanics, materials, control and decision systems.

DEDICATED RESSOURCES :

- Renishaw AM400 machine.

- 3D Systems 3D ProX300 machine.

- Test machine Gleeble 3500.

- Support of laboratory test facilities (equipement list here, in french).

COMPETENCIES :

- Design of parts.

- Topological optimization.

- Modeling manufacturability rules.

- Behavior machine and process control.

- Analysis and optimization of finishing operations (machining, polishing, etc.).

- Analysis of microstructure and metallurgy generated by laser fusion.

- Numerical simulation and advanced laws of behavior of materials.

- Nonisotropic behavior laws with localized defects.

- Numerical modeling and optimization of process parameters.

- Characterization of the mechanical properties.

- Non-destructive checks.

- Mechanical tests.